Built for Demanding Environments.

Quartz broadcast floors offer slip-resistant strength, vibrant texture, and unmatched durability — ideal for settings that demand both performance and aesthetics.

What is a Quartz Broadcast System?

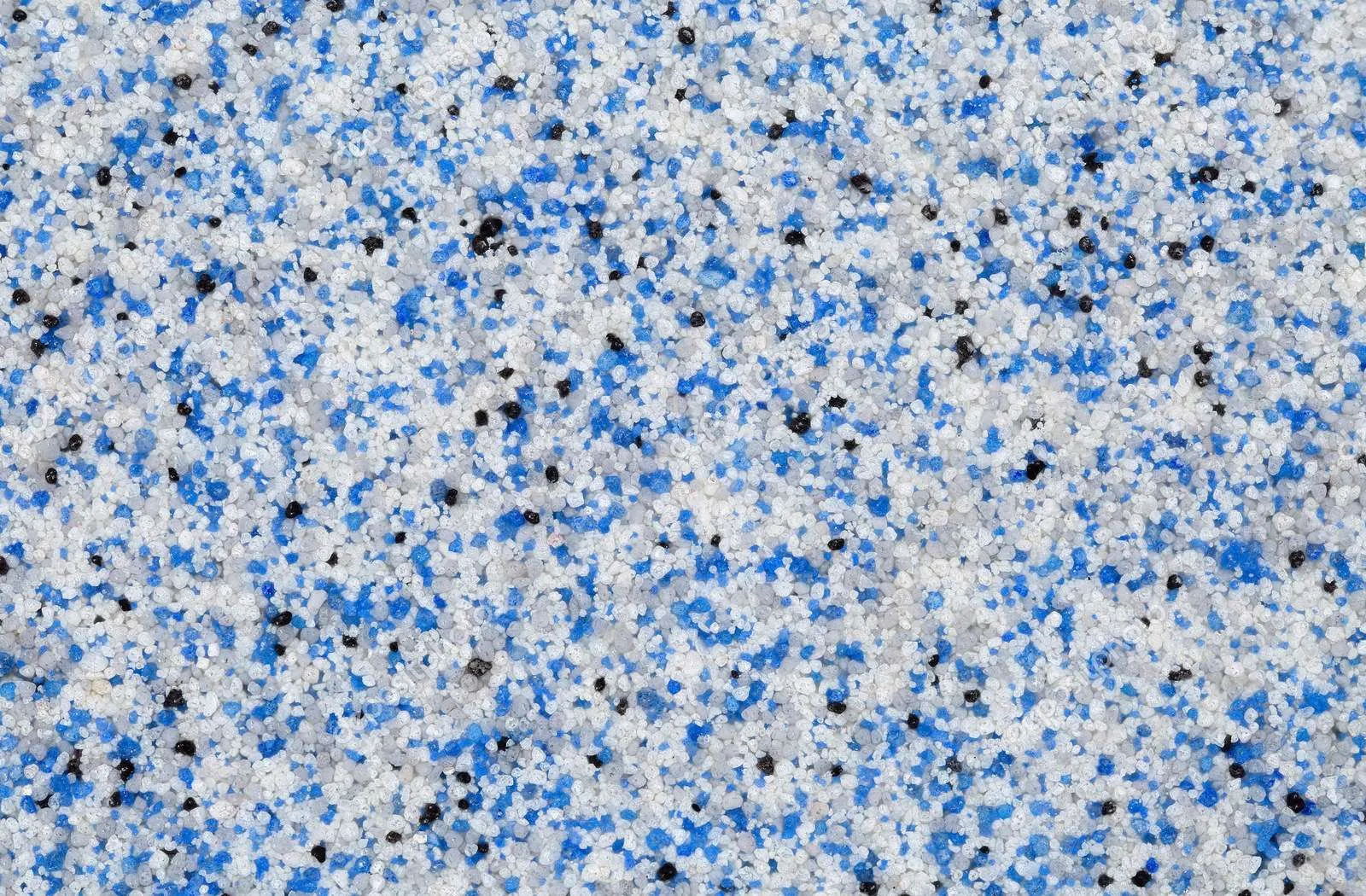

Quartz systems are multi-layer resinous coatings that incorporate colored quartz granules broadcast into an epoxy or urethane base. These systems are designed for high-traffic, high-impact environments, offering aggressive traction and chemical resistance without sacrificing visual appeal. The broadcast quartz is locked in place with clear binders and topcoats to create a seamless, ultra-durable surface.

Why chose a Quartz Broadcast System

Slip-Resistant Texture – Ideal for wet or safety-critical areas

Heavy-Duty Durability – Withstands foot traffic, rolling loads, and abrasion

UV-Resistant Topcoats – Maintains color and clarity in sun-exposed areas

Excellent Chemical Resistance – Handles cleaners, oils, acids, and salts

Sanitary & Seamless – No joints or grout lines, easy to clean and disinfect

Build Thickness – Typically installed at 40–60 mils depending on use

Custom Blends Available – Choose from single-color or multi-color quartz. Browse our Quartz blends below.

Best Applications

Quartz floors are built for performance — perfect where safety, hygiene, and traction are critical.

Residential

Garage floors

Home gyms

Utility rooms

Mudrooms

Laundry areas

Outdoor patios or steps (with UV-stable topcoat)

Commercial

Commercial kitchens

Public restrooms

Veterinary clinics

Grocery and retail backrooms

Schools and locker rooms

Hospitals and healthcare facilities

Specialty

Food and beverage processing

Warehouses

Packaging lines

Clean rooms

Cannabis grow rooms

Maintenance corridors & utility spaces

Our Process (How We Install Quartz Broadcast Systems)

Step 1: Surface Preparation

We mechanically grind the concrete using an industrial grinder and high-quality metal-bonded diamonds to remove surface contaminants and open the pores. This achieves a CSP (Concrete Surface Profile) of 3-4, ideal for resinous coating systems. Edges and tight areas are detailed with hand grinders to ensure complete, uniform prep across the entire slab.

Step 4: Optional Second Quartz Broadcast

For additional build, durability, or more aggressive texture, we apply a second broadcast layer. This includes another coat of epoxy followed by a second round of full quartz broadcast. It's ideal for industrial, food-grade, or heavy-traffic areas.

Step 2: Moisture Vapor Barrier (Pigmented)

We apply a pigmented moisture vapor barrier that serves both as moisture protection and the base color beneath the quartz. This layer anchors into the open concrete and improves adhesion — especially critical in industrial or wet environments.

Step 3: Quartz Broadcast

While the epoxy base is wet, colored quartz granules are broadcast at full coverage. This creates a textured surface with excellent slip resistance. After curing, excess quartz is removed and the surface is scraped smooth.

Step 5: Grout Coat (Optional for Build & Texture)

For full broadcast systems, we apply a clear grout coat to lock in the quartz and reduce surface texture. This adds strength and prepares the surface for a clean, uniform topcoat.

Step 6: Protective Topcoat

A chemical-resistant topcoat is applied — gloss — tailored to your environment. For heavy-duty or wet areas, we can include a non-slip additive to maintain traction under foot traffic and spills.

Ready for a Floor That Can Take a Beating?